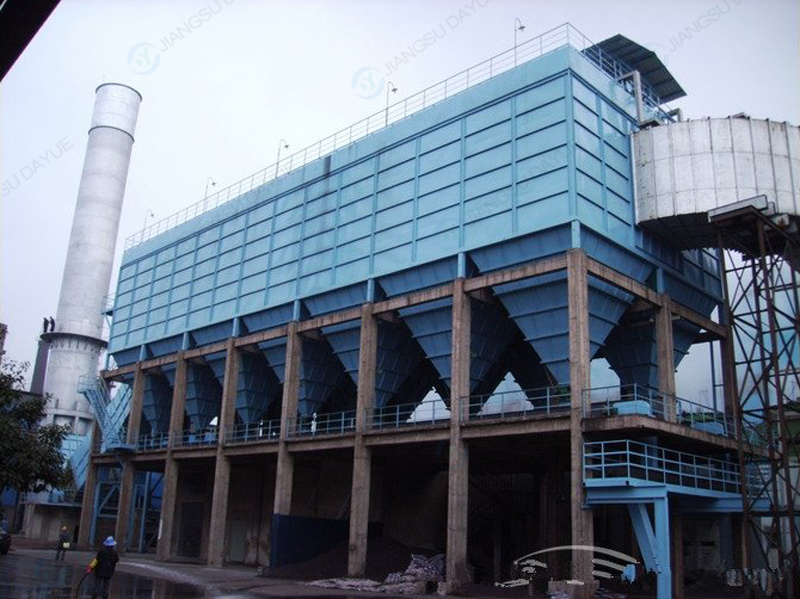

RDMC Series Low Pressure Jet Pulse Long Filter Bag Dust Collector

RDMC long filter bag pulse dust collector is made on the basis of injected pulse and cleaning dust technology integrate with domestic and oversea advanced technology to dedust gas with large air volume demand.It has the advantages of section reverse flowing and pulse dedusting,which makes up for deficiency of intensity during sub-room and reabsorbing in pulse cleaning dust.The collector improves the efficiency,largely reduces frequency and uses the submerged pulse valve to reduce air pressure and energy consumption,prolong the service life of using filter bag and pulse valve,and enhance combined property greatly.It is widely used in building materials,metallurgy,petrochemical,food,iron&steel,coal,biomass power plant gas dedusting&material recovery application at room or high temperature.

Main Features

1.By using pulse technology,the dust collector has a high&efficient of dust removal capability.It have the features of low leakage rate,low energy consumption and small occupancy of area.The equipment operate stable,and yield excellent payback in return,which is applied for dust removal in several industries,such as metallurgy,building materials,machines,chemistry,electricity,light industries and etc.

2.The body is designed with excellent sealing system.Robust seal materials are used in making the inspection door with low air leakage.User may apply diesel on the seal area to check air leakages.

3.The opening of outlet is compacted with low gas resistance.

4.Applies cleaning chamber separation and pulse jet dust cleaning concept,dedust cycle is operated at extended time interval and low energy consumption.Thus,it can improve two times service life of filter bag and valves.

5.Field site can realize filter bag replacement without shutdown the system and routine inspection work will not impact on system operation.

6.Filter bags design installation at top zone body ease up user inspection and create friendly working environment.

Note:

1.The air volume is calculated in accordance with filtration speed of 0.8-1.0m/min。Selection of suitable model based on application requirement.

2.Selction of filter materials shall be based on the process requirement.

RDMC84 Technical Specifications

| Model/Technical Parameter | Jun-84 | Jul-84 | Aug-84 | Sep-84 | Oct-84 | Dec-84 | 84-14 | 84-16 | 84-18 | C84-20 | |

| Air volume(万m3/h) | 5.93-8.892 | 6.91-10.5 | 7.7-11.6 | 8.9-13.3 | 9.6-14.5 | 11.8-17.7 | 13.8-20.7 | 15.4-23.2 | 17.8-26.6 | 19.2-29.0 | |

| Total filter area(m2) | 1235 | 1440 | 1613 | 1850 | 2015 | 2460 | 2880 | 3226 | 3700 | 4030 | |

| G..Weight | 30 | 35 | 40 | 45 | 50 | 60 | 70 | 80 | 90 | 100 | |

| Filter | Quantity | 504 | 588 | 672 | 756 | 840 | 1008 | 1176 | 1344 | 1512 | 1680 |

| Specification | Φ130×6000 | ||||||||||

| Filter valve | Quantity | 36 | 42 | 48 | 54 | 60 | 72 | 84 | 96 | 192 | 216 |

| Specification | 3 inches | ||||||||||

| Resistance(Pa) | 1200-1600 | ||||||||||

| Air consumption(m3/min) | 2--4 | ||||||||||

| Discharging density(mg/Nm3) | ≤30 | ||||||||||

| Air leakage rate(%) | <3 | ||||||||||

| Pressure(Mpa) | 0.2-0.4 | ||||||||||

RDMC168 Technical Specifications

| Model/Technical Parameter | 168-5 | 168-6 | 168-7 | 168-8 | 168-9 | 168-2×5 | 168-2×6 | 168-2×7 | 168-2×8 | 168-2×9 | ||||||||||

| Air volume(万m3/h) | 9.6-12.0 | 11.52-14.4 | 13.4-16.8 | 15.36-19.2 | 17.28-21.6 | 19.2-24.0 | 23.04-28.8 | 26.85-33.6 | 30.72-38.4 | 34.56-43.2 | ||||||||||

| Total filter area(m2) | 2000 | 2400 | 2800 | 3200 | 3600 | 4000 | 4800 | 5600 | 6400 | 7200 | ||||||||||

| G..Weight | 50 | 60 | 70 | 80 | 90 | 100 | 120 | 140 | 160 | 180 | ||||||||||

| Chamber(Pcs) | 5 | 6 | 7 | 8 | 9 | 10 | 12 | 14 | 16 | 18 | ||||||||||

| Filter | Quantity | 840 | 1008 | 1176 | 1344 | 1512 | 1680 | 2016 | 2352 | 2688 | 3024 | |||||||||

| Specification | Φ130×6000 | |||||||||||||||||||

| Filter valve | Quantity | 60 | 72 | 84 | 96 | 108 | 120 | 144 | 168 | 192 | 216 | |||||||||

| Specification | 3 inches | |||||||||||||||||||

| Resistance(Pa) | 1200-1600 | |||||||||||||||||||

| Air consumption(m3/min) | 2--4 | |||||||||||||||||||

| Discharging density(mg/Nm3) | ≤30 | |||||||||||||||||||

| Air leakage rate(%) | <3 | |||||||||||||||||||

| Pressure(Mpa) | 0.2-0.4 | |||||||||||||||||||

YDMC 220 (Double Rows)Technical Specifications

| Model | 220-2×5 | 220-2×6 | 220-2×7 | 220-2×8 | 220-2×9 | 220-2×10 | 220-2×11 | 220-2×12 | |||||||

| Air volume(万m3/h) | 34.46-43.08 | 41.36-51.7 | 48.25-60.31 | 55.41-68.93 | 62.04-77.54 | 68.93-86.16 | 75.82-94.78 | 82.72-103.39 | |||||||

| Total filter area(m2) | 6631 | 7958 | 9284 | 10610 | 11937 | 13263 | 14589 | 15916 | |||||||

| G..Weight | 179 | 215 | 251 | 287 | 323 | 359 | 359 | 431 | |||||||

| Chamber(Pcs) | 10 | 12 | 14 | 16 | 18 | 20 | 20 | 24 | |||||||

| Filter | Quantity | 2200 | 2640 | 3080 | 3520 | 3960 | 4400 | 4400 | 5280 | ||||||

| ecification | Φ160×6000 | ||||||||||||||

| Filter valve | Quantity | 220 | 264 | 308 | 352 | 396 | 440 | 484 | 528 | ||||||

| Specification | 3 inches | ||||||||||||||

| Resistance(Pa) | 1200-1600 | ||||||||||||||

| Air consumption(m3/min) | 6--10 | ||||||||||||||

| Discharging density(mg/Nm3) | <30 | ||||||||||||||

| Air leakage rate(%) | <3 | ||||||||||||||

| Pressure(Mpa) | 0.2-0.4 | ||||||||||||||

RDMC 220 (Four Rows)Technical Specifications

| Model/Technical Parameter | 220-4×5 | 220-4×6 | 220-4×7 | 220-4×8 | 220-4×9 | 220-4×10 | 220-4×11 | 220-4×12 | |

| Air volume(万m3/h) | 68.92-86.316 | 82.72-103.4 | 96.5-120.62 | 110.28-137.86 | 124.08-155.08 | 137.86-172.32 | 151.6-189.56 | 165.52-206.78 | |

| Total filter area(m2) | 13263 | 15916 | 18568 | 21221 | 23874 | 26526 | 29179 | 31832 | |

| G..Weight | 358 | 430 | 502 | 574 | 646 | 710 | 790 | 862 | |

| Chamber(Pcs) | 20 | 24 | 28 | 32 | 36 | 40 | 44 | 48 | |

| ilter | Quantity | 4400 | 5280 | 6160 | 7040 | 7920 | 8800 | 9680 | 10560 |

| pecification | Φ160×6000 | ||||||||

| ilter valve | Quantity | 440 | 528 | 616 | 704 | 792 | 880 | 9680 | 1056 |

| pecification | 3 inches | ||||||||

| Resistance(Pa) | 1200-1600 | ||||||||

| Air consumption(m3/min) | 6--10 | ||||||||

| Discharging density(mg/Nm3) | <30 | ||||||||

| Air leakage rate(%) | <3 | ||||||||

| Pressure(Mpa) | 0.2-0.4 | ||||||||

.jpg?x-oss-process=image/resize,w_100/quality,q_100)