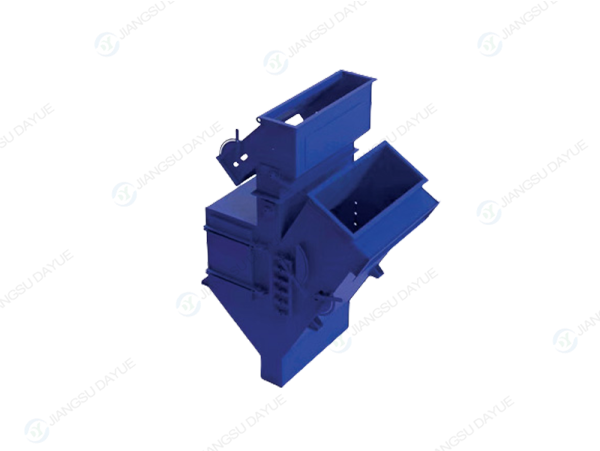

Hr-Zl Series Unpowered Powder Selection Machine

The principle of structure

By the control of air flow,flow direction and gravity,the gravity classifier can realize 0-5mm material classification.The fed material and primary air enters into the classifier from the top,the direction of air flow changes 120°,and leaves the classifier with fine particles through the blades.The coarse particles fall down to the bottom of the classifier because of the gravity itself then can’t be flowed with the air,and discharges from a valve.Secondary air blowing from the bottom of the blades passes the curtain of falling particles mandatorily.These coarse particles nearing the classification point enters into the eddy in the heart-shaped cavity secondary air flow which changed its director.When enter the classifier,the captured fine particles and other particles pulled by the eddy all gather into the powder collector and will be recycled at last.The air throttle of secondary air can be adjusted simply by hand.It can change the particles granularity of classification.There is no moving part in material flow area,so the maintenance requirement of this machine is the lowest.For abrasive material,wear liners are used in some area in order to guarantee the long operating life of equipment.

Function:

separate 0-5mm sized particles,control the dust content less than 1%.

1.Easy to adjust,4 parts for adjustment as:material feeding control,first ventilation control,secondary ventilation control,air output volume control.It can control the air flow and powder content easily.

2.Energy saving,previous solution is classifier&dust collector;no motor is required in this series of equipment,the main power is focus on dust collector.Thus,it saves the electricity investment.

3.Simple structure,few material contact parts,wear parts adopt the wear-resisting treatment developed by“Tarzan”,little abrasion,low cost of maintenance.

| Serial Number | Model | Processing sand volume(TPH) | Ventilation volume (additional)m3/h | Can be equipped with drum air volume(m3/h) |

| 1 | HR-ZL1200 | 50-70 | 16000~23000 | 8000 |

| 2 | HR-ZL1500 | 70-90 | 23000~30000 | 12000 |

| 3 | HR-ZL1600 | 90-110 | 30000~37000 | 15000 |

| 4 | HR-ZL1800 | 110-150 | 37000~50000 | 18000 |

.jpg?x-oss-process=image/resize,w_100/quality,q_100)