YGM Series High Pressure And Medium Speed Mill

High-pressure medium-speed grinding mill is referred to as high-pressure grinding mill.It is an enhanced type of Raymond grinding mill of our company,which is optimized and upgraded by combining successful experience at home and abroad and popular Raymond grinding technology.The biggest improvement is the addition of a high-pressure spring system in the grinding roller part.It has outstanding advantages such as a wider range of grinding materials,finer grinding particle size,and higher grinding efficiency.It is an efficient and energy-saving grinding mill equipment.It is widely used in material processing fields in mining,construction,building materials,water conservancy and hydropower,metallurgy,chemical industry and other industries,such as calcium carbonate crushing and processing,gypsum powder processing,power plant desulfurization,non-metallic mineral powder making,coal powder preparation and other industrial grinding projects.

High-pressure medium-speed grinding mill is widely used in quartz,feldspar,calcite,limestone,talc,ceramics,marble,granite,dolomite,bauxite,iron ore,barite,bentonite,coal gangue,coal and other materials,and Mohs hardness below 7,humidity less than 5%,non-flammable and explosive materials.

Workingprinciple

In the main machine of high-pressure medium-speed mill,a high-pressure spring with a pressure of 1000-1500 kg is fastened on the roller hanger.After starting to work,the roller rotates around the main axis and rolls close to the grinding ring under the action of the high-pressure spring and centrifugal force.Its rolling pressure is 1.2 times higher than that of the Raymond mill under the same power conditions,so the output is greatly improved.When the material to be ground enters the grinding chamber,it is scooped up by the shovel and sent to the grinding roller and the grinding ring for rolling.The rolled powder is brought into the analyzer with the circulating air of the blower.The qualified fine powder flows into the cyclone powder collector with the air and is the finished product.The large particles fall back to the re-grinding.The circulating air returns to the blower and repeats the above process,and the remaining air enters the pulse dust collector for purification.When the roller and the grinding ring reach a certain wear,adjust the length of the high-pressure spring to maintain a constant rolling pressure between the roller and the grinding ring,thereby ensuring stable output and fineness.

Performance advantage

1.Higher production capacity with the same power

Compared with other mills,the output is increased by 10-20%under the same power conditions,and the grinding force of the grinding roller on the material is increased by 800-1200kg under the action of the high-pressure spring.

2.The grinding particle size is adjustable,and the finished product particle size is finer.

The particle size range is wide,generally up to 0.045 mm(325 mesh),and the finest can reach 0.038 mm(1400 mesh)

3.Easy maintenance and reliable sealing.Good dust removal effect.

The analyzer is easy to adjust,and the grinding device adopts overlapping multi-stage sealing with good sealing performance.It fully meets the national dust emission standards

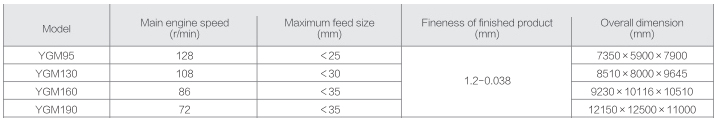

TECHNICAL PARAMETERS TABLE I

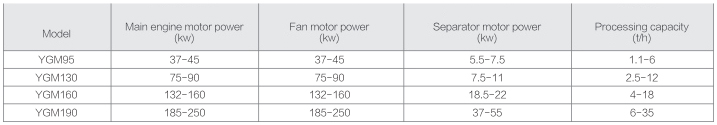

TECHNICAL PARAMETERS TABLE II

Note:

The output in the table refers to the standard of ground calcite.Technical data is subject to change without further notice.Please refer to the product manual for details.