HGM Series Ring Roller Micro Grinding

Brief Introduction

Ultrafine powder mill is a professional mill for fine powder, micro powder and ultrafine powder. It is commonly called three-ring mill, three-ring micro powder mill, medium speed, three-ring mill. This machine overcomes the defects of traditional industrial Raymond mill in terms of application range, output, fineness, energy consumption, service life, etc. It is an ideal substitute for traditional mills such as Raymond mill and ball mill, and is widely used in my country's metallurgy, electric power, chemical industry, steel, building materials, coal and other industries. Ultrafine powder mill is mainly suitable for medium and low hardness, non-flammable and explosive brittle materials with Mohs hardness < 6, such as calcite, chalk, limestone, dolomite, kaolin, bentonite, talc, mica, magnesite, illite, pyrophyllite, vermiculite, sepiolite, attapulgite, rectorite, diatomite, heavy stone, gypsum, pigment, clay, alunite, stone density, fluorite, phosphate rock, potash ore, pumice and hundreds of other materials. The fineness of the output product can be adjusted within the range of 325 mesh-2500 mesh.

Working Principle

The ultra-fine powder mill is composed of a mill main machine,a powder selector,a powder collector,a dust collector,a fan,a muffler,a soundproof room,a crusher,an elevator,a silo,a feeder,etc.After the large pieces of material are crushed into small particles by the crusher,they are sent to the silo by the elevator,and then through the feeder and the inclined guide pipe,the material is evenly sent to the bulk material plate on the upper part of the turntable.When the mill is working,the grinding roller rotates and rolls in the ring channel.Under the action of centrifugation,the material is scattered to the periphery and falls into the grinding cavity,and is stamped,rolled and ground by the grinding roller in the ring channel.As the high-pressure fan continuously sucks the air inside the equipment,the material after multi-layer crushing is brought into the powder selector,and the high-speed rotating impeller screens it.The unqualified material falls back to be re-ground,and the qualified material enters the cyclone powder collector with the air flow.Dust with higher density falls down and is discharged from the discharge valve at the bottom as the finished product.Fine dust with lower density enters the dust suppressor with the airflow and adheres to the surface of the filter bag.The high-pressure airflow is controlled to be ejected instantly from the inside of the filter bag during pulses.The dust adhering to it falls down due to the shaking of the filter bag.The conveyor at the bottom sends the materials collected from the two places out for finished product packaging.

Performance Advantages

1.Low investment cost.Under the same fineness,it has less investment than air flow mill,low cost and short recovery period.

2.Under the same finished product fineness and power consumption,the output is more than 45%higher than that of air flow mill and stirring mill.

3.Low loss of wearing parts.All wearing parts are made of highly wear-resistant materials,which have a longer service life than the wearing parts of ordinary grinding equipment.4.The operation in the grinding chamber is safe and reliable.Compared with ordinary grinding machines,the sealing performance is better

5.The finished product fineness is high,and the product fineness can reach 325-2500 mesh

6.Environmental protection and pollution-free.It adopts high-efficiency pulse dust collector.There is no dust pollution during the operation of the whole set of equipment.It is equipped with muffler and muffler room to reduce noise.It is produced in accordance with national environmental protection standards and plays an environmental protection role in the surrounding environment.

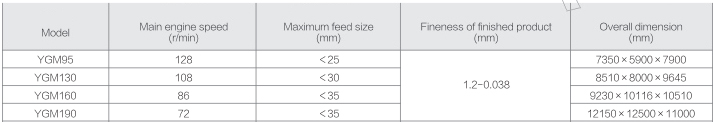

TECHNICAL PARAMETERS TABLE I

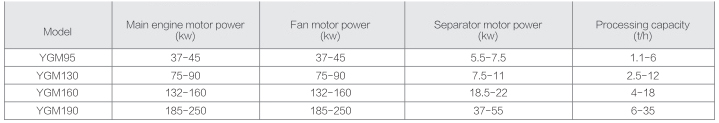

TECHNICAL PARAMETERS TABLE II

Note:

The output in the table refers to the standard of ground calcite.The technical data is subject to change without further notice.Please refer to the product manual for details.